Functions of screw spikes in railway track

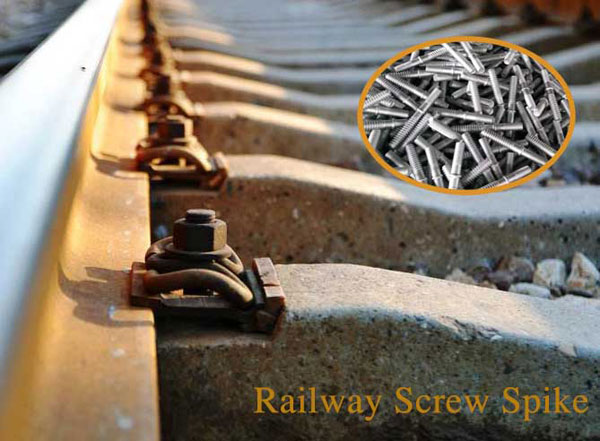

Railway screw spikes are important railway accessories used to fasten rails, sleepers, and rail fasteners together. They play a vital role in the railway system, ensuring the stability and safety of railway tracks, and are suitable for different types of track structures, including high-speed railways, heavy-haul railways, and ordinary railways. Railroad screw spikes are key parts to ensure safe railway operation and are suitable for use in various harsh environmental conditions, such as high temperature, cold, humidity, etc. As an important part of the railway system, the quality of railway screws is directly related to the safety and efficiency of railway transportation.

What is the function of screw spikes in railway tracks?

-

Fixed rail

The most basic function of the railway screw spike is to fix the rail to the sleeper to ensure that the rail does not move or loosen when the train passes. Through the screw thread design, the screw spikes can be firmly embedded in the sleepers, providing a strong fixing force.

-

Maintain track spacing

Railway screw spikes help maintain the standard spacing (gauge) of the track by holding the rails in a predetermined position. This is one of the important factors to ensure smooth and safe operation of trains. Accurate track gauges can prevent trains from derailing and improve transportation safety.

-

Earthquake and impact resistance:

Railroad screw spikes have good seismic and impact resistance properties and can effectively absorb and disperse the vibration and impact forces generated when trains pass by. This reduces friction between sleepers and rails and extends the service life of railway facilities.

-

Prevent track deformation:

When trains run at high speed or are heavily loaded, the track may be affected by various stresses and external forces and deform. The strong holding feature of railroad screw spikes helps prevent the track from moving sideways or twisting, keeping the track straight and stable.

-

Facilitates track maintenance and replacement

The design of the railway screw spikes makes them easy to install and remove, making it easier for routine maintenance and replacement of the track. The thread design allows the spikes to be quickly loosened and retightened using special tools when they need to be replaced or adjusted, which improves repair efficiency and reduces maintenance costs.

-

Improve the safety of rail systems

Railway screw spikes greatly improve the overall safety of railway track systems by firmly securing rails and maintaining standard spacing on the track. Especially on tracks with high frequency and heavy load transportation, screw spikes can ensure the long-term stability and safety of the track.

Production requirement of railway screw spikes

Material requirements

- Commonly used materials: 45# steel, 50# steel, 60# steel and other alloy steels.

- Hardness requirements: Heat-treated railroad screw spikes should meet the specified hardness standards, such as 200 to 260 HB (Brinnell hardness).

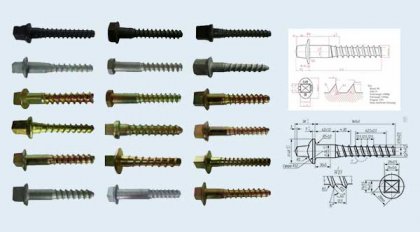

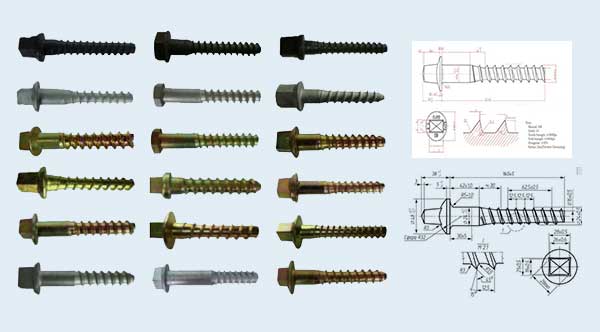

Dimensions and specifications

- Diameter: Common diameters are 16mm, 18mm, 20mm, 22mm, etc.

- Length: The length of railroad screw spikes usually ranges from 120mm to 200mm, depending on the sleeper thickness and installation requirements.

- Thread type: Railway screw spikes typically have thicker threads for enhanced retention and vibration resistance.

Surface treatment

Standards and specifications

- Chinese standards: TB/T 1495 (railway standards and specifications), GB/T 1346, etc.

- American standards: ASTM A66, AREMA (American Railroad Engineering and Maintenance Association standards).

- European standards: EN 13481, UIC 864-2, etc.

Why choose us?

AGICO product advantages

- Safe and reliable: Our railway screws have excellent mechanical properties and durability, ensuring that the track system can maintain a high degree of safety and reliability in harsh environments.

- Wide application: Suitable for various types of railway construction and maintenance, including high-speed railways, heavy-haul railways, subways light rails, etc., and widely used in domestic and foreign railway markets.

- Easy to install and maintain: The design of railway screws makes it very convenient to install and remove, which greatly improves construction efficiency and also facilitates daily inspection and maintenance.

Application

FAQ about Railway Screw Spike

What is a railway screw spike?

What materials are railway screw spikes made from?

What are the advantages of using screw spikes over traditional rail spikes?

- Increased Holding Power: The threaded design provides a stronger grip and resistance to loosening, especially in high-vibration environments.

- Durability: Railway screw spikes are less likely to work loose over time compared to traditional spikes, reducing maintenance needs.

- Resistance to Corrosion: Many railway screw spikes are coated with anti-corrosion materials, which extends their lifespan in harsh environmental conditions.

- Flexibility: Suitable for use with both wooden and concrete sleepers, making them versatile for various types of railway tracks.

How are railway screw spikes installed?

What standards govern the manufacturing and use of railway screw spikes?

- AREMA (American Railway Engineering and Maintenance-of-Way Association) for North America.

- EN 13481 and UIC 864-2 for European railways.

- GB/T standards for Chinese railways.

- Other local standards may apply depending on the country and specific railway requirements.

Can railway screw spikes be reused?

What is the typical lifespan of a railway screw spike?

Are there specific screw spikes for different types of railway sleepers?

How do railway screw spikes contribute to rail safety?

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!