Railway Sleepers

Railway sleepers, also known as railroad ties or rail fasteners, are crucial components of the rail track system. They are typically categorized based on the material used in their construction, which can include concrete sleeper, wooden sleeper, plastic sleeper, composite sleeper, and steel sleeper.

Although they have a simple structure, railway sleepers play an essential role in maintaining the integrity of the railway track. They support the rails, help to maintain the alignment of the track and distribute the pressure exerted by the train wheels to the underlying track bed. Regardless of the material, all railway sleepers must possess a certain level of flexibility and elasticity. This allows them to absorb and cushion the pressure from passing trains, returning to their original shape quickly after each impact.

Wooden Sleepers

Wooden sleepers, also known as railroad ties, are the oldest and most widely used type of railway sleeper globally. Made from hardwoods like oak and treated pine, they are typically treated for anti-corrosion and oil immersion to extend their lifespan. Despite the rise of concrete and composite sleepers, wooden sleepers continue to dominate the market due to their flexibility, availability, and durability.

Key Materials for Wooden Sleepers

Common hardwoods used for wooden sleepers include oak and pine, which are known for their high oil content and long growth cycles. The oil content enhances the sleeper’s wear resistance, preventing cracking. Pine, with its fine grain and flexibility, is particularly effective at absorbing pressure, improving the sleeper’s longevity and performance.

Benefits of Wooden Sleepers

Wooden sleepers offer several advantages, including excellent insulation, good flexibility, lightweight, ease of processing, and minimal temperature sensitivity. Properly treated, they can last up to 15 years, making them a reliable and cost-effective choice for railways.

Types of Wooden Sleepers

Wooden sleepers are classified by structure and application:

By Structure: Horizontal, longitudinal, and short sleepers.

By Application: Ordinary, bridge, and pillow sleepers.

AGICO wooden sleepers are primarily made from southern pine or Mongolian pine, treated with traditional oil methods. They are available for various applications, including normal tracks, turnouts, and bridges. Wooden sleepers remain essential to railway infrastructure due to their combination of durability, flexibility, and cost-effectiveness.

AGICO wooden sleepers are primarily made from southern pine or Mongolian pine, treated with traditional oil methods. They are available for various applications, including normal tracks, turnouts, and bridges. Wooden sleepers remain essential to railway infrastructure due to their combination of durability, flexibility, and cost-effectiveness.

Wooden Sleeper for Normal Railway Line

Common wooden sleeper is used in the main line of railway track. GB standard has 2 types: type I with 16cm×22cm×250cm; type II with 14.5cm×20cm×250cm.

| Type | Length(mm) | Width(mm) | Thickness(mm) |

|---|---|---|---|

| KTMB | 2000(±12) | 254(+12,0) | 127(+11,-3) |

| type Ⅰ | 2500(±60) | 220(±10) | 160(0,-5) |

| type Ⅱ | 2500(±60) | 220(±10) | 145(0,-5) |

| Standard | 2600~4800(±60) | 240(±10) | 160(0,-5) |

Wooden Sleeper for Turnout

Wooden sleeper apply for turnout zone at the junction of railway lines might has other large sizes

| Type | Length(mm) | Width(mm) | Thickness(mm) |

|---|---|---|---|

| KTMB | |||

| Normal | 2600~4850 | 220 | 160 |

| Standard | 2600~4800 | 240 | 160 |

Wooden Sleeper for Bridge

wooden sleepers for bridge are used for railtracks built on bridge sections.

| Type | Length(mm) | Width(mm) | Thickness(mm) |

|---|---|---|---|

| KTMB | |||

| Standard | 3000 | 220 | 240/260/280/300 |

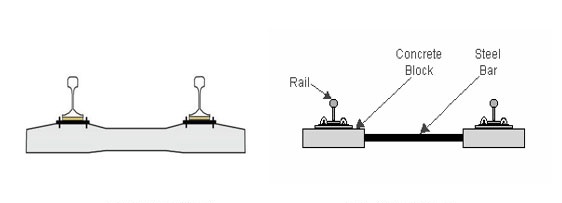

Concrete Sleepers

Concrete sleepers, known as railroad ties in North America and rail sleepers in the UK and Australasia, are rectangular supports made of concrete used in railway tracks. Primarily used in high-speed railway construction, concrete sleepers play a key role in distributing the load to the track ballast and subgrade, ensuring the rails remain stable and properly spaced at the correct gauge. AGICO's concrete sleepers are known for their long service life and excellent longitudinal and lateral resistance within the ballast.

Types of Concrete Sleepers

Concrete sleepers are classified based on their application, including:

- Prestressed Sleepers

- Pre-tensioned Sleepers

- Post-tensioned Sleepers

- Two-block Sleepers

Concrete Sleepers: Advantages and Disadvantages

Advantages:

- Stability: Enhanced lateral stability and strong vertical and horizontal resistance.

- Rigidity: High rigidity leads to smoother rail deflection and reduced dynamic gradient.

- Elastic Cushion: Even orbital elasticity due to a high elastic cushion.

- Durability: Long service life (40-50 years), corrosion-resistant, and low maintenance.

- Sustainability: Saves wood, resists decay, and is suitable for various road conditions.

Disadvantages:

- Irregularities: Potential operational challenges due to irregularities.

- Increased Power Requirements: Higher track power needs due to rigidity.

- Limited Applications: Not suitable for bridges or crossings with smaller sizes.

- Heavy Weight: Difficult transport and installation due to their weight.

Maintenance Performance Requirement for Concrete Sleeper

Concrete Sleepers must be suitable for efficient transportation on special rolling stock and be stable for stacking on rolling stock or on-site. Medium-duty sleepers must also be suitable for installation by a conventional track laying equipment of a type used for partial resleepering. For track adjustment, rails must move freely on the rail seats. To achieve this, fastening systems must be able to be released for adjustment and re-fastened on completion of the work.

Composite Sleepers

Composite sleepers, also known as synthetic sleepers, are made from continuous glass fiber-reinforced polyurethane foam. Combining the properties of reinforced plastic composites and foam materials, composite sleepers offer a unique blend of the advantages of natural wood and plastic. These sleepers feature high strength, a superior specific modulus, and suitability as structural materials. They are lightweight, heat-insulating, chemical-resistant, electrically insulating, and resistant to aging. Like wood, composite sleepers allow for nailing and riveting.

Composite sleepers are primarily used in high-speed railways and subways, particularly in situations where concrete sleepers are unsuitable, such as ballasts, bridge tops, and platforms.

Features of Composite Sleepers

- Ease of Installation: Simple on-site installation reduces maintenance and repair needs.

- Stable Geometry: Maintains the distance between rails, guard rails, and sleepers while preserving excellent and stable line geometry.

- Durable Surface: Resistant to peeling and wear over time.

- Customizable Sizes: Sleeper height is at least 140mm, width at least 200mm, and length customizable to customer requirements.

- Quality Standards: Manufactured in compliance with CJ/T399-2012.

Steel Sleepers

Steel sleepers produced by AGICO are versatile and suitable for various applications, ranging from meter-gauge railways to mainline and heavy-haul freight routes. These sleepers are manufactured in compliance with international standards such as UIC 865 and BS 500-2000. Both the steel material and sleeper length can be customized to meet specific customer requirements.

UIC-865 Steel Sleeper Specification:

| UIC-865 Serie Steel Sleeper | |||

|---|---|---|---|

| Grade | Standard | Material | Length |

| UIC50 |

UIC865 |

according to customer requirement |

according to customer requirement |

| UIC60 | |||

| P43 | |||

BS-500 Steel Sleeper Specification:

| BS-500 Series Steel Sleeper | |||

|---|---|---|---|

| Grade | Standard | Material | Length |

| BS75A | BS 500-2000 |

according to customer requirement |

according to customer requirement |

| BS75R | |||

| BS80A | |||

| BS90A | |||

| BS100A | |||

| BS113A | |||

Get In touch Now!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!