Rail Clip

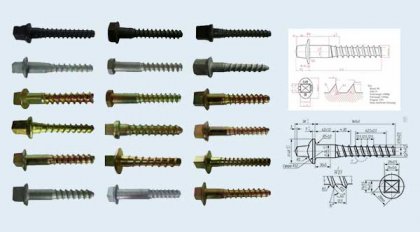

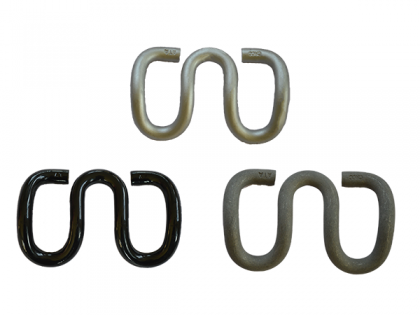

Varieties of rail clips

| Series | Type | Hardness | Material | Fatigue life | Surface | Standard |

|---|---|---|---|---|---|---|

|

|

E1,E2,E3 |

44-48HRC |

|

For Dia.18 is 3 million cycles without breaking. For Dia.20 is 5 million cycles without breaking. |

plain (oiled), Oxide black, color painting or according to customer requirement. |

DIN17221, BS970, GB/T1222 |

| E1609 | ||||||

| E1809 | ||||||

| E1817 | ||||||

| E2001 | ||||||

| E2006 | ||||||

| E2009 | ||||||

| E2055 | ||||||

| E2056 | ||||||

|

Vossloh clip& Forged rail clip |

SKL1 |

42-47HRC

|

||||

|

PR rail clip |

PR309 |

44-48HRC |

||||

| PR401 | ||||||

| PR601 | ||||||

| PR85 | ||||||

| Customized production of rail clips are available according to your drawings or samples! | ||||||

Parameters of Main Rail Clip Products

| Model | Diameter | Weight | Material |

|---|---|---|---|

| Type III | Ø18 | 0.80kg/pc | 60Si2MnA |

| E1609 | Ø16 | 0.43 kg/pc | 60Si2MnA |

| E1809 | Ø20 | 0.61kg/pc | 60Si2MnA |

| E1813 | Ø18 | 0.62kg/pc | 60Si2MnA |

| E2001 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2007 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2009 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2039 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2055 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2056 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2063 | Ø20 | 0.80kg/pc | 60Si2MnA |

| PR85 Rail Clip | Ø13 | 0.25kg/pc | 60Si2MnA |

| PR309A | Ø19 | 0.85kg/pc | 60Si2MnA |

| PR401 | Ø20 | 0.97kg/pc | 60Si2MnA |

| PR415 | Ø20 | 0.95kg/pc | 60Si2MnA |

| PR601A | Ø20 | 1.03kg/pc | 38Si7 |

| SKL 1 | Ø13 | 0.48kg/pc | 60Si2CrA |

| SKL 3 | Ø13 | 0.48kg/pc | 60Si2CrA |

| SKL 12 | Ø13 | 0.53kg/pc | 38Si7 |

| SKL 14 | Ø13 | 0.53kg/pc | 60Si2MnA |

| Special Rail Clip | Ø13 | 0.48kg/pc | 60Si2MnA |

| Russia Rail Clip | Ø18 | 0.58kg/pc | 60Si2MnA |

| Deenik Clip | Ø25 | 0.49-0.68kg/pc | 60Si2MnA |

|

Single Anti- Theft |

Ø20 | 0.25kg/pc | 60Si2MnA |

Process procedures of rail clips

- Raw material purchasing

- Shearing

- Heating to forging temperature

- Forming

- Hardening

- Tempering

- Surface treatment

- Inspection-Packing

The spring steel bar should first be sheared as per length required. By convention, the sheared rods are heated to the 950 ℃ to 1000 ℃, and then the heated bars are transferred to power press for forging. Three sets of dies and fixtures are kept as per drawing before hammering. The forged rail clips are conveyed to quenching tank. After checking dimensional accuracy and quench hardness, rail clips would be sent to the next procedure for tempering to achieve appropriate toughness in the spring. The final product will be packed after serious inspection.

Rail clips from AGICO

As a professional rail clip manufacturer and supplier, AGICO continues to offer you both high quality rail clips with various standards and comprehensive product tracking service. Rail clips from AGICO are all designed with high precision and made up of premium grade spring steel. Within more than 20 years’ rail clip production experience, AGICO has been the largest and most competitive production base of rail clips in China, qualified to tender nationally large and medium scaled rail projects under the China Railway Corporation.

In addition, we have the most modern production lines for rail clips, from material cutting, medium frequency heating, 3-time punch forming, quenching, tempering and inspection to packing. We have a daily production capacity of 100,000 pieces rail clips and our rail clips can be customized according to customers’ requirements.

Inspection machines for finished rail clips:

- Brinell Hardness Tester

- Carbons and Sulfur Analyzer

- Rockwell Hardness Machine to test metallic materials

- Automatic Impact Testing Machine

- Metallographic Microscopes

- Automatic High-Speed Analyzer

- Fatigue Testing Machine

- Metallographic Specimen Polishing Machine

- Metallographic Specimen Pointing Machine

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!